Accessory Belt Drive Systems (ABDS) are heroes of automotive performance. Our latest focus is on tensioners, explaining their role in maintaining smooth engine function, reducing vibration, and extending belt life. Discover why timely replacement is vital and how to choose the right components to maximize your vehicle's performance. Perfect for mechanics, garages, and car enthusiasts looking to optimize engine reliability and efficiency.

- What is an Auxiliary Tensioner?

Vehicles using multi-ribbed belts normally incorporate automatic tensioner(s) within the accessory drive system. An automatic tensioner applies a constant force on the belt, compensating for belt length changes due to wear and constantly changing operational loads generated within the accessory drive system. This automatic re-tensioning function reduces maintenance by eliminating the need to re-tension belts periodically, as the correct tension will be applied for the life of the belt. Older engines having a manual tensioner installed, require periodic re-tensioning, to ensure the correct tension is maintained.

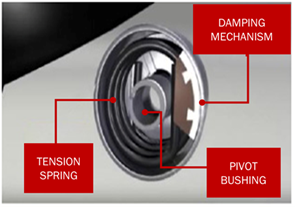

The main difference between an automatic and a manual tensioner is the presence of a powerful spring, and damping mechanism located inside the tensioner housing. The pulley mechanism pivots around the housing and generates a constant tension on the belt.

- Key Functions of Tensioners

Tensioner Operating Principle: Tensioners have three main functions, 1) Pulley Offset, 2) Tension, 3) Damping.

1) Pulley Offset: The Tensioner pulley centre must align with all other pulley centres within the drive system ensuring the belt runs in the same plane.

2) Tension: More accessories, generates more load on the drive system, more load, therefore requires more tension, Incorrect system tension can lead to incorrect component operation such as (power steering, air conditioning) eventually resulting in failure, an internal heavy-duty spring, controls the tension.

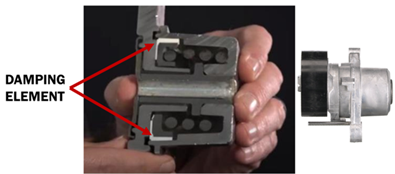

3) Damping: Smoothest oscillations and vibrations in the drive system each time accessories turn on, off, or during the engine’s combustion cycles, all generate variations in belt tension, the internal damping element controls the damping.

- Signs of Wear and When to Replace

Tensioners wear over time: The damping mechanism operates like a braking system drum brake arrangement; an internal heavy-duty spring forces the (half-moon shaped) damping mechanism against the inside of the tensioners housing generating friction. Spring fatigue will eventually affect and reduce spring tension over time, as the spring is constantly compensating as the damping mechanism wears.

Illustrations below show (1.) a New and (2.) Worn damping mechanism, the white friction (half-moon shaped shoe) shows the new damping mechanism has a thicker profile compared to the worn damping mechanism which has a thinner profile.

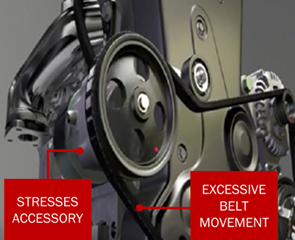

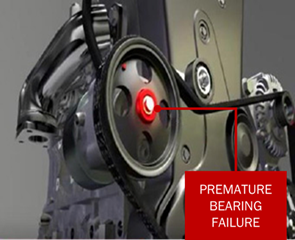

When the damping mechanism has worn it reduces the tensioners capabilities to control belt fluctuations or belt slapping (3.) belt slapping transfers vibrational stresses, and generates noise within the drive system, eventually leading to part failure. The slapping effect of the belt also generates heat which will transfer into bearings operating within the accessory drive system, this increase of heat can lead to grease purge from bearings (4.) leading to bearing - pulley, and belt failure.

A Worn tensioner pivot bush will cause excessive tensioner arm movement (5.) allowing the (arm and belt) to track into or away from the engine, this tracking effect generates misalignment problems within the drive system, drastically reducing belt life and drive system reliability. The belt tensile cord pack can become damaged if the belt tracks into and fouls against the engine (6.) causing a weakened area to the side of the belt, eventually leading to failure of the belt.

Tracking - Misalignment problems caused by the worn pivot bush will also lead to uneven loading of the belts tensile cord pack, increasing belt noise levels, and accelerating rib wear of the belt, leading to premature belt failure.

TENSIONERS CAN CYCLE 1 BILLION TIMES IN 100,000 MILES (160,000 KM).

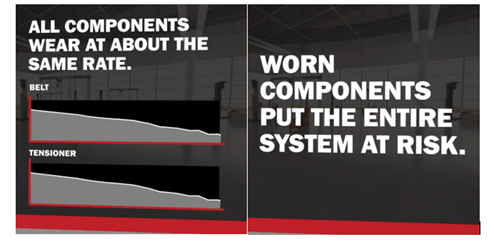

Many moving components exist within an ABDS system, the components are individually manufactured but they are designed to work together as a system! The accessory belt drive system performance depends on every component working together! (7.) These components are wear & tear parts! Accessory drive components wear at about the same rate. (8.) Gates recommends to always change multi-ribbed belts and metal components at the same time.

- Why Choose Gates Micro-V® Kits?

Gates Micro-V® kits are the perfect solution (9.) for an efficient replacement of the accessory belt drive system, one kit containing one or more gates branded multi-ribbed belts and matching metal parts, tensioner(s), idler(s) & water pump.

Kits are also available with matching torsional vibration dampers (TVD) - and / or – (clutch pulley – overrunning alternator pulley - OAP) saving the time and trouble to select all these parts separately.

- OE-QUALITY MICRO-V® KITS FROM GATES, THE POWER TRANSMISSION SPECIALISTS.

Gates Micro-V® tensioners are OE equivalent or even better in both performance and fit. With Gates Micro-V® tensioners, you will get performance and fit that are equal to or better than the original.

ONE NAME, ONE BOX, ONE SOLUTION